New Technologies to Bolster Mine Revenue in the Near Term

Take-Aways from MINExpo 2016 and the Connected Mine

Viewing the booths and innovations as the MINExpo 2016 show in Las Vegas this last week of September, one gets a resounding message that new ideas are being explored in both technology solutions and business models that will change the shape of modern mining. The resulting mandates for mine management will speed development of technology road maps for the planning and integration of new solutions that will bring about new economic models for the US mine industry upswing.

Viewing the booths and innovations as the MINExpo 2016 show in Las Vegas this last week of September, one gets a resounding message that new ideas are being explored in both technology solutions and business models that will change the shape of modern mining. The resulting mandates for mine management will speed development of technology road maps for the planning and integration of new solutions that will bring about new economic models for the US mine industry upswing.

On the technology front, vendors showcased a variety of smart mining solutions that result in what is being known as the Connected Mine concept. Here is an overview of modern mine workflow, highlighting a sample case of those developments.

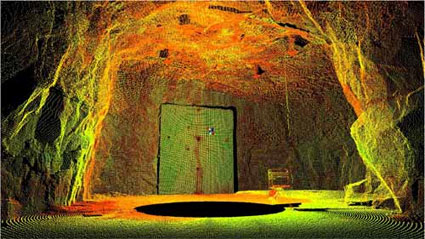

A laser site scan of the underground mine site provides degrees of visualization better than any surveyor shooting points. This data can be uploaded to the central office to show supervisors overbreak and underbreak, and can show clear before & after images to mark progress or incident reporting. That data is reviewed to weigh the risks and resources on an update to next day’s schedule. Mining supervisors can more easily produce actionable insights, and can do so from better decision support  tools now on the market.

tools now on the market.

In the case of surface mining, surveying from the sky through the use of aerial drones will greatly enhance terrain mapping with more detail than before. The quality of the resulting data into enterprise systems can fuel open pit design software projects to get a 3-D view and map different materials to plan resources on the site.

In all, new planning software and on-board productivity applications make it easier to make more informed and quicker decisions for safe and profitable mining days.

Machinery Advancements

Machinery is on-site the following day. Through GPS and RFID integration, operator’s safety is vastly improved due to onboard collision avoidance, now with added intelligence to exclude false warnings, and added fatigue detection.

For surface mining, a remote rig can be guided from an operation booth 1000 feet away from the drill rig. Known as teleremote drilling, this solution can benefit the operator in multiple ways, including the elimination of the crew’s non-drilling duties (such as area inspection, raking and cutting pile, hole plugging), elimination of vibration, and better visibility. This translates to improved performance and greater field productivity.

Production Data

More choices of field communications mean more efficient and more frequent data uploads from in-vehicle PCs to the cloud. 4G LTE, Wi-fi (802.11) and GSM can transport data on location of haulers, vehicle status and diagnosis, and payload detection. There are examples of in-vehicle PC platforms from Advantech that meet the communications need.

With these data innovations in the case of payload per site locations, operators can begin the process of calculating increases in the value of the ore through the day, rather than waiting until it reaches the mill.

With these data innovations in the case of payload per site locations, operators can begin the process of calculating increases the value of the ore through the day, rather than waiting until it reaches the mill.

With these data innovations in the case of payload per site locations, operators can begin the process of calculating increases the value of the ore through the day, rather than waiting until it reaches the mill.

It is data like this that will spurn adoption of cloud services that enable the Connected Mine to aggregate data from a variety of operational technology systems such as dispatch, fleet management, fatigue detection, information from data historians, data warehouses, IP cameras and more.

There is even more on the horizon. The landscape has been expanded from what was previously merely RTU and M2M technology to IoT, with mining sites on a trajectory of intelligent compiled data from multiple units being transmitted to enterprise-side repositories. Through these developments, big data advancements make it possible for the mining industry to experience new economies in boosting production and value.

Global Mining heavyweights are changing the world of mining as we know it. It is time for mine management to keep focus on solutions that can deliver real value in the industry for productivity and safety advances.

10%+ Increase in Productivity & Cost Efficiency

• Rugged Vehicle-Grade Design for harsh mining operation

• NFC & CAN Bus to monitor driver’s productivity

• Real-Time mine site status monitoring for production efficiency

20%+ Accident Reduction by Advanced Driver Assistance System

• Intelligent video analytics for driver behavior coaching

• Intelligent voice recognition system to eliminate driver distractions

• In-Vehicle Surveillance & TPMS for accident prevention