Considerations for Dependable Industrial IoT for Manufacturing

Introduction

An important benefit of IIoT is the ability to design real-time industrial control data to flow into Big Data and analytic software applications for business intelligence calculations. The result is the ability for organizations to search, monitor, analyze that data to not only minimize future expenses, but to ultimately deliver better value to their customers.

An important benefit of IIoT is the ability to design real-time industrial control data to flow into Big Data and analytic software applications for business intelligence calculations. The result is the ability for organizations to search, monitor, analyze that data to not only minimize future expenses, but to ultimately deliver better value to their customers.

An established system integrator required compute and networking hardware to successfully implement an Industrial IoT solution for a multinational consumer goods manufacturer for the process manufacturing of food/beverage and personal care products. Since the Operational Data was isolated from the rest of the IT network in their organization, the manufacturer had a company mandate to implement IoT at their facilities, predominantly to gain business intelligence.

With a complicated manufacturing process, as many as 6 machines were involved for a single process step. Each machine required sensory data to be measured at a fast rate. The challenge was the proper selection of equipment to manage the flow of data on machinery daily usage patterns, to optimize for productivity and measure the impact on operating expenses over time. Getting this data to the Business application layer with a dashboard view that the SI designed would insure the visibility in the central office of every output from systems at different facilities from a global scope.

The Systems Integrator and the customer chose the value setting to be measured. In turn the Systems integrator then selected their protocol framework based on the data format designed by the customer. The OP protocol would be converted at the PC Gateway to pass upstream to the enterprise/cloud side, where it was decided that MQTT would be the conversion transfer language. This led to the further set of requirements:

- • An IIoT solution that can pass an interoperable OP data format to enterprise side.

- • A 3G data transfer solution from the facility via VPN and optimized for high-latency conditions and unreliable networks.

- • Remote management capability to monitor status of the gateway and IoT network equipment.

- • A dependable, low-power solution with longevity

Solution Description

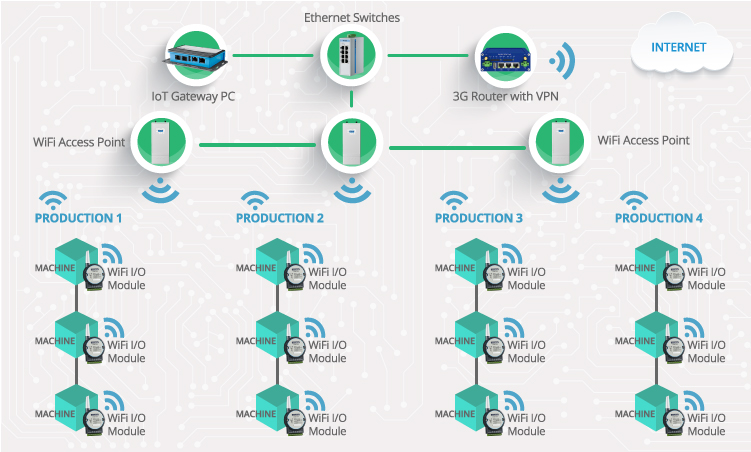

WISE-4050 Wi-Fi I/O Modules are connected to each machine’s laser counting sensor node, enabling the transfer of sensor data upstream.

UBC-221 Compact IoT Gateway PC for compiling and transmitting sensor data in MQTT protocol securely via Wi-Fi further to the cloud server.

EKI-6331 Wi-Fi Access Points - Each can handle traffic from over 12 wireless clients employing multiple security authentication types.

EKI-5528 Monitored Ethernet Switch allows monitoring and management of the networking status remotely from the central command center.

BB-RT3G-310 3G Router - Runs the reformatted data from Wi-Fi 802.11 b/g/n to the customer VPN server via 3G cellular service, ultimately transferring sensor data to the cloud server.

IIoT Solution transmits sensor data up via Wi-Fi, Ethernet and 3G cellular to the Cloud and Application Layer

Due to its flexibility, Wi-Fi was chosen as the transport for data from the WISE modules up to the UBC-221 Gateways. It is there that the proprietary customer gateway-side application provides the data filter function before passing to the application layer.

The key aspect of the production-side solution is that it must pass data in an interoperable format to the Enterprise side for IoT applications. The system integrator chose Splunk, a software service for machine data as the platform for the IoT data management layer. The system integrator set the task to compile and set-up mapping of the client’s IoT data ensuring a successful integrated into the Splunk platform.

The UBC-221 Gateway is using processing and filtering using MQTT and RESTful - the most recent and widely used data service for IoT – to pass the data that is protocol-agnostic, ensuring the data is readable on the enterprise application side. The gateway performs the data handling function and can filter to allow only tagged data sets to send for proper repository allocation, mapping the traditional data, and route it to various locations.

The counting data is the ideal measurement of the efficiency of machine output for this projects scope. Measuring trends, such as a decrease in count within certain timeframes, can determine the necessity to set an adjustment remotely, send a technician on-site, and/or replace equipment.

With the Advantech onboard management on the UBC-221 supporting bi-directional data transfer, the system integrator can offer that the customer use their VPN tunnel to get remote access to the UBC-221, WISE modules, and EKI Access Points, providing remote views for ad hoc remote maintenance.

The EKI-6331 Wi-Fi Access Points provide the secure uplink to the 3G Router, featuring built-in strong wireless output power to handle environmental noise to transmit the data to the last step in the flow of the integration.

The BB-RT3G-310 3G Router receives the Wi-Fi transmission and performs the 3G uplink at the facility network’s edge to send to the cloud. Meeting the client’s strict security requirement, the router uses a VPN tunnel offering the most secure authentication. The 3G router also utilizes network redundancy to mitigate high-latency or unreliable networks, thus the customer can ensure high bandwidth, secure flow of data even at their most remote facilities.

Conclusion

The system’s data pass of count data to the application layer means it is an enabler of such business analysis as Big Data calculations for production optimization.

The system integrator saw the benefit of working with a single supplier to team with who could bring both IoT gateway and networking background to solve the project challenges.

There is a future-proof benefit to the value that an IIoT solution such as this one. Once a data can be gathered, compiled and passed in an interoperable format, the data is there for Big Data calculations for production optimization and Predictive Maintenance.